The crude castor oil contains various pigments and impurities, so it needs to be refined. Due to the high viscosity of castor oil, its refining conditions are harsher than ordinary vegetable oils.

Alkali refining

Because the phospholipid content in castor oil is less (less than 0.3%), it can be directly refined by alkali. Saponify castor oil with alkali at 60°C. The method is to put the crude oil into an alkali refining tank, measure its acid value, start stirring to make the oil evenly mixed, heat and control the oil temperature at 25-30°C. Add liquid caustic soda, add all the caustic soda at one time within 10 min, and at the same time use rapid stirring (60 r/min]. When the oil soap begins to separate, heat up at a speed of 1C/min, and reduce the speed (30 r/min). Stop stirring after reaching 90 ° C, and discharge the material after standing still; the required lye can also be evenly sprayed on the oil surface within 20-30 mm, stirred for 15 min and then allowed to stand for 25 min, and then started to stir at 1 C/min. When the oil temperature rises to 85 C, stop heating and stirring, let it stand for 100 minutes and release the soapstock to be processed. At this time, the sesame oil is a viscous vegetable oil with brownish-yellow tinge of green, containing some impurities.

Washed

It can be washed with a salt solution such as 30% sodium chloride. After the soap stock is cleaned, spray the boiling water of the above components on the oil surface, stir and let it stand for nearly 1 hour, put the washing water in the oil-water separation tank, and repeat the operation again. When using the continuous water washing method for spray washing, the amount of sprayed water should be controlled so that it is equal to the amount of discharged water. Stop spraying when the pH value of the discharged water is 7, let it stand for 40 minutes, and let off the waste water. The semi-finished product is sucked into the evaporator by vacuum, added hot water with a temperature above 90°C, stirred, and then allowed to settle for 15 minutes. Vacuum the semi-clean oil in the upper layer into the washing tank and heat it to 90°C, then wash it three times with hot water at the same temperature, each time the water consumption is 20% of the oil weight, after each washing, settle for 30 minutes and release the washing wastewater.

Dehydration

The resulting crude castor oil was dehydrated under a vacuum of 0.089 MPa.

bleaching

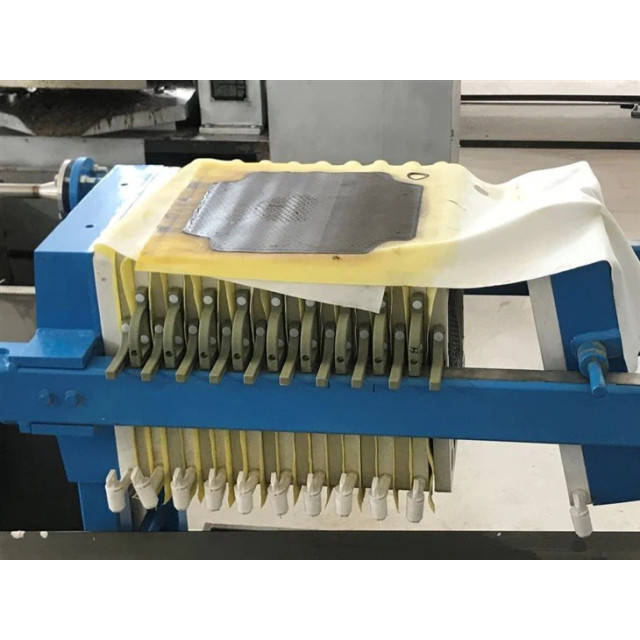

The castor oil dehydrated by alkali refining is decolorized with dry activated carbon and acid clay. Inhale the dehydrated oil into the decolorization tank, inhale 2-3% of the crude oil weight activated carbon and acidic natural soil, stir and decolorize at a temperature of 95 C, and the decolorization can also be carried out under pressure. The coloring time is 15 min-1 h. After decolorization, let stand and filter to obtain refined decolorized castor oil.

Deodorization

Put in steam, vacuum deodorize at 180°C for 2-3 hours, cool down, and release the vacuum at 90°C to obtain high-quality fungus and sesame oil.

|

Capacity |

Tanks |

Volume |

|

500kg/day |

2 |

200kg |

|

1T/day |

4 |

200kg |

|

1.5T/day |

4 |

500kg |

|

3T/day |

4 |

1T |

|

6T/day |

4 |

2T |

|

9T/day |

4 |

3T |

|

10T/day |

4 |

5T |