Oil refining is based on the difference of oil and the impurities in the physical and chemical properties, separate the grease and impurity by professional technical ways, in order to improve the oil edible quality, storagest ablity and safety process.Oil refining process is divided into chemical refining and physical refining.

The refining technician and equipment we adopt suits different kinds of vegetable oil process.According to the materials and capacity, we can use batch, continuous, physical and chemical refining design.The product

oil can reach first to fourth grade.Guarantee the highest quality in lowest cost.

EDIBLE OIL REFINERY TECHNOLOGY: Oil refining is based on the difference of oil and the impurities in the physical and chemical properties, separate the grease and impurity by professional technical ways, in order to improve the oil edible quality, storagest ablity and safety process.Oil refining...

The crude oil is refined and fractionated to give a high quality oil. Fractionation can separate soft fat and hard fat. Palm oil fractionation can obtain palm oil products with different melting points such as 8 degree, 10 degree, 14 degree, 18 degree, 24 degree, 33 degree, 44 degree and 55...

First Grade Cooking Oil Fully Refining Plant Newly developed Oil oxidation is an important factor affecting the quality of edible oil, which is also called fatty acid rancidity. After the fat is decomposed, free fatty acids are generated, and they are divided into "saturated VS unsaturated...

Effect of deodorization process conditions on the quality of sunflower oil 1. Effect of deodorization conditions on the deodorization effect of PAEs in sunflower oil Under the condition of deodorization time of 100 min, the removal rates of DBP, DEHP and DINP were 9.4%, 61.9% and 61.8%...

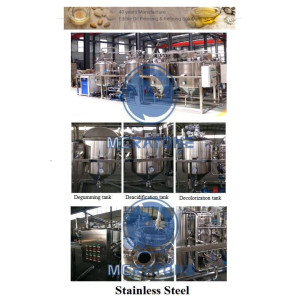

Palm Oil Refinery Decolorization Equipment How to get a clear and transparent palm oil? Traditional cooking oil refining process, usually including degumming, deacidification, dissolution, decolorization, dewaxing, deodorization, decolorization process is an essential link of oil refining,...

Applications of avocado oil in cosmetics Traditional use of avocado butter In ancient Africa, avocado butter was obtained from the kernel of the avocado fruit through traditional processing methods. It is obtained by spreading the flesh of the avocado, which is naturally dried and cold pressed....

This article introduces the specific steps of cocoa butter production line, through this article, you can understand how cocoa butter is produced.

Effect of deodorization process conditions on the quality of sunflower oil 1. Effect of deodorization conditions on the deodorization effect of PAEs in sunflower oil Under the condition of deodorization time of 100 min, the removal rates of DBP, DEHP and DINP were 9.4%, 61.9% and 61.8%...

The process for walnut oil production includes the following steps: shelling, separation of the kernel from the shell, pressing, filtration, and cold pressing to obtain walnut oil. The crude oil obtained from pressing is called crude oil or "mao you" in Chinese. Crude oil contains water,...

The crude castor oil contains various pigments and impurities, so it needs to be refined. Due to the high viscosity of castor oil, its refining conditions are harsher than ordinary vegetable oils. Alkali refining Because the phospholipid content in castor oil is less (less than 0.3%), it can be...

Palm kernel oil, also known as palm kernel oil, is obtained from the kernel of the palm fruit. Palm kernel oil contains a lot of lower fatty acids, so its properties are very different from palm oil, but very similar to coconut oil. Fresh palm kernel oil is milky white or yellowish in color, has...

Palm Oil Refinery Decolorization Equipment How to get a clear and transparent palm oil? Traditional cooking oil refining process, usually including degumming, deacidification, dissolution, decolorization, dewaxing, deodorization, decolorization process is an essential link of oil refining,...