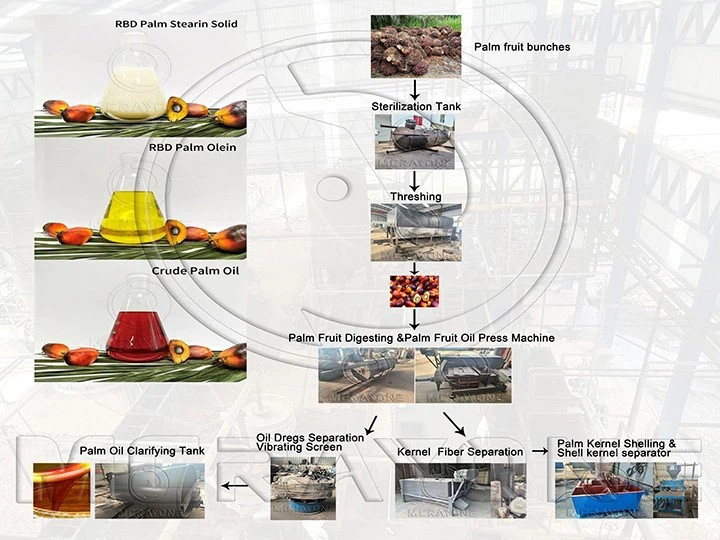

Palm Fruit Production Line

Palm oil is rich in carotene (0.05%-0.2%), which is dark orange-red in color. This pigment cannot be effectively removed by alkali refining, and the oil color can be stripped to a generally light yellow through oxidation. Palm oil will also gradually decolorize under the influence of sunlight and air. Crude palm oil (CPO) and palm meal (PE) can be obtained from palm pulp through the process of boiling, crushing and squeezing.

This is a panoramic view of our factory:

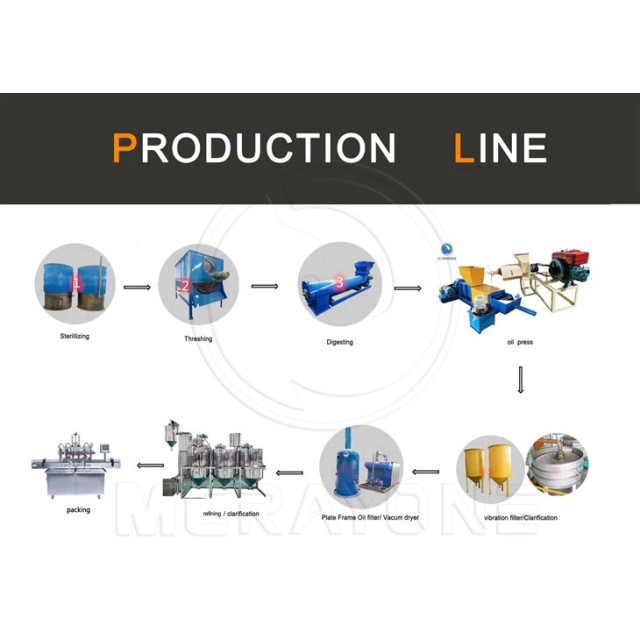

Press procedure:

(1) The fruit bunches are sent to the virgin crushing plant within 24 hours after picking (to prevent high levels of free fatty acids).

(2) Steaming: 150℃ is time-consuming and will cook the fruit bunches to pieces.

(3) After the fruits fall, the lift starts and drops the machine, the fruit skewers are separated, the skewers are burned as fertilizer, and the goods are sent to the silo.

(4) Pressing: screw press. The pressed cake is extruded from the machine head, containing fruit core (not broken, containing palm kernel oil), and the liquid part flows out from the lower port, and is filtered and sent to the butterfly centrifuge to extract palm oil.

(5) Press kernel oil.

and the pressed cake obtained in step (4) is sent to the mesh separation port.

a) The squeezed and squeezed fruit pulp fibers are processed manually to produce fiberboard and paper;

b) The fruit core is sent to the crusher by air, and the core shell is broken to separate the kernel particles, which are used as fuel;

c) The kernel particles are pressed Machine, filter and butterfly separator are used to obtain crude palm kernel oil.