Effect of dehulling and frying seeds for pressing

on the flavor of concentrated sunflower seed oil

Sunflower seed is one of the eight major oil crops and the fourth largest oil crop in the world after palm, soybean and rapeseed. Sunflower oil contains up to 48.3%-74.0% linoleic acid and is rich in vitamin E, sterols and other bioactive components, which has high nutritional value. In recent years, the process of frying sunflower seeds and then pressing them to produce concentrated sunflower oil has been popularized and applied.

Sunflower seeds contain 20% to 30% of shells, which contain a variety of natural pigments such as anthocyanin and melanin, and the wax content accounts for about 60% of the total lipids in the shells. Pressing oil with shells will cause these components to enter the gross oil and thus adversely affect oil refining and product quality, and also reduce the utilization value of sunflower seeds due to the high crude fiber content (about 20%) in sunflower seed cake meal. It was found that sunflower seed hulls adversely affected the sensory quality and product quality of cold pressed sunflower oil.

Hulling or peeling of oilseeds is an important process in the pretreatment of oil production

The test results proved that the two types of sunflower seed oil differed in clear flavor, burnt flavor and greasy flavor score. Compared with hulled sunflower oil, sunflower oil with shelling and pressing has obvious burnt flavor, but weak clear flavor and oily flavor, little difference in nutty flavor, and slightly higher sweet flavor and roasted flavor score. The stronger burnt flavor of shelled sunflower oil may be due to the fact that the sunflower seed shells were heated during the frying process to produce a flavor similar to burning wood. The overall flavor score of dehulled pressed sunflower oil was higher than that of shelled pressed sunflower oil. Therefore, dehulling and pressing had a positive effect on the overall flavor enhancement of sunflower oil.

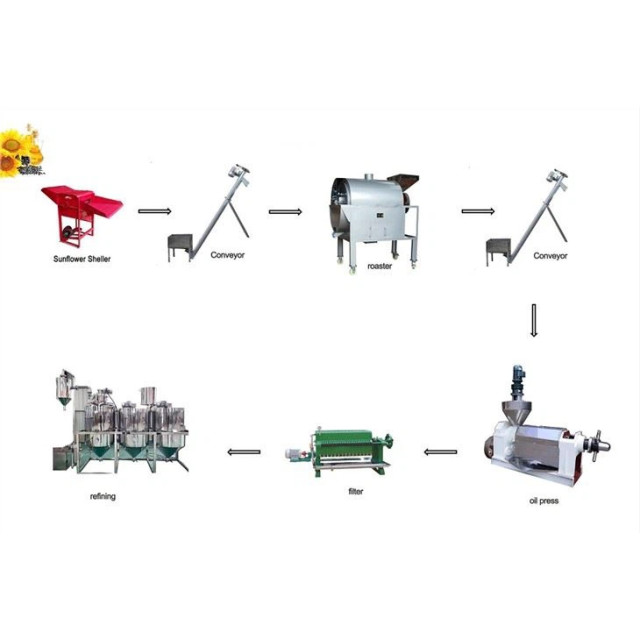

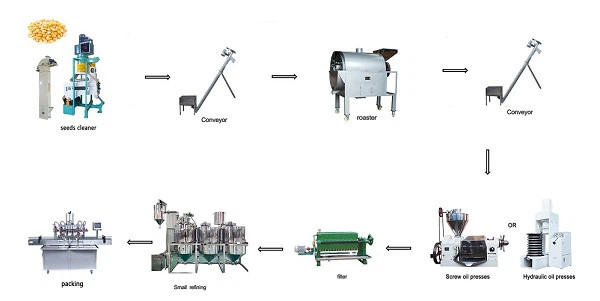

Sunflower Seed Oil Production Line:

processing dehulling - roasting - pressing - filtering - refining --Packaging

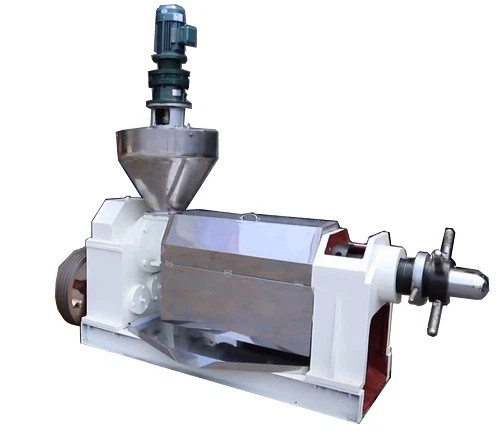

| Oil press machine | |||||||

| NO. | Picture | Model | Power | Capacity | Weight | Package Size | Remarks |

| 1 |

|

RF130-A Multi-functional Screw Oil Press | 23.9 kw-4P | 450-500 kg/h 10-12 T/24hrs |

1850 kg | 5.69CBM | With temperature control box/filte/Saving grinding preheating time |

| 2 |

|

ZX 130 Screw Oil Press | 18.5 kw-6P | 820 kg | 1.65CBM | Single machine/Suitable for large production lines/lower oil residue rate | |

| 3 |

|

RF130-S Simple Auto-temperature control oil press | 21.7 kw | 880 kg | 2.53CBM | With temperature control box Saving grinding preheating time/ lower oil residue rate | |

| 4 |

|

ZX150 Screw Oil Press | 30 kw-6P | 750-850 kg/h 16-20T/24hrs |

1340 kg | 2.25CBM | With electric control box/reducer Adjustable speed of feeding/ Suitable for large production lines |

| 5 |

|

1240 kg | Single machine/Suitable for large production lines/Cost-effective | ||||