Cocoa butter refining

Cocoa butter and has the characteristic flavor of cocoa, has a very short plasticity range, below 27 ℃, almost all solid (27.7 ℃ began to melt). With the increase in temperature, it melts rapidly, and melts completely at 35℃. Therefore it is a kind of grease that is both hard and dissolves quickly. Cocoa butter is the most stable edible oil known, and contains natural antioxidants that prevent spoilage, allowing it to be stored for 2-5 years and allowing it to be used for purposes other than food.

Cocoa butter is divided into natural cocoa butter and deodorized cocoa butter, depending on the production and process. Natural cocoa butter is light yellow in color and has a natural cocoa aroma; deodorized cocoa butter is based on natural cocoa butter by physically removing impurities, color and odor from the cocoa butter. Deodorized cocoa butter has a bright lemon yellow color and no odor. Natural cocoa butter is widely used in the production of chocolate, cakes and other food products; deodorized cocoa butter is generally used in the production of high-grade cosmetics and pharmaceuticals, but rarely in the production of food.

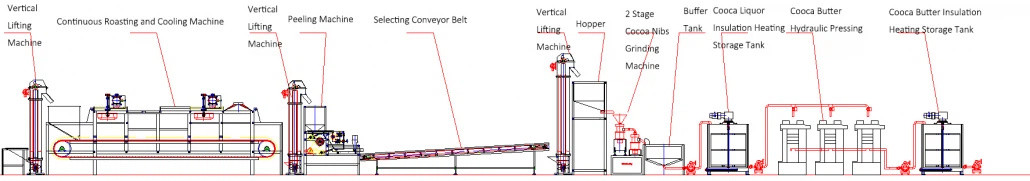

Pretreatment:

Harvesting->Cleaning->Stone removal->Roasting->Screening

The pretreatment of cocoa beans is the first key step in the entire production process. First, the freshly harvested cocoa beans need to be carefully cleaned to remove the soil, branches and other impurities attached to the surface of the bean shells. The cleaned cocoa beans are placed in a dry and ventilated place to further remove excess moisture.

Next, the stone remover will automatically screen out stones and other hard objects mixed in the cocoa beans. This step is essential for protecting subsequent processing equipment.

After that, the cocoa beans enter the roasting stage. Roasting is a key step in adjusting the moisture content of cocoa beans, which not only affects the taste of cocoa beans, but also determines the quality of the final product. After a carefully controlled roasting process, the moisture in the cocoa beans is adjusted to the appropriate level, ready for subsequent grinding and pressing.

Finally, the roasted cocoa beans are sent to the screening machine, and the cocoa beans of uniform size and high quality are selected through screens with different apertures.

Grinding and pressing section:

Pre-grinding->Grinding->Pressing

Grinding is the core link in cocoa butter production. First, the pre-ground cocoa beans are fed into a finer grinder. After being cut and rubbed by high-speed rotating blades, the cocoa beans gradually become fine cocoa liquid blocks.

The ground cocoa liquid blocks are fed into the cocoa butter press machine. Under great pressure, the oil in the cocoa liquid blocks is fully squeezed out to form primary cocoa butter.

Refining part:

Refining is a key step in improving the quality of cocoa butter. During the cocoa butter refinery machine process, the phospholipids and other impurities in the oil are first removed by dephosphorization; then deacidification is carried out to reduce the acid value of the oil; then dehydration is carried out to further reduce the moisture content in the oil; followed by decolorization, and the pigments in the oil are removed by adsorbents such as activated carbon; deodorization is the last step in the refining process. The deodorization system usually uses high temperature and vacuum conditions to remove volatile odor substances in the oil. The deodorized cocoa butter is pure and odorless, and is widely used in food processing processes such as baking, chocolate making and candy making. The purity and stability of deodorized cocoa butter make it one of the indispensable raw materials in the food industry.

Our Strengths Of Refinery Machine:

1. Dehydration tank: tank thickness of at least 4mm, high temperature, high vacuum dehydration.

2. Decolorization tank: 105-130 degrees decolorization, can be designed to cycle decolorization, more thorough.

3. Up to 800 total accessories.

4. Welding: Our factory is very strict in welding 304 stainless steel, which ensures that the service life of the equipment will not be shortened and the quality of the oil will not be reduced due to connection problems during use.

5. Vacuum: Once our vacuum Roots pump is turned on, the vacuum in the tank will reach -0.099. The vacuum is a factor that directly affects the quality of the oil. If the vacuum is not enough, the peroxide value in the oil will be too high, and the oil quality will be poor.

6. Separate deodorization system: There are not many manufacturers on the market that make separate deodorization systems. We will customize them according to the customer's own requirements, and the oil products will meet CE standards.