At present, the world's coconut products are still mainly dried coconut, which is the main raw material for the production of coconut oil. Dried coconut oil can be obtained by pressing or extracting coconut oil, which is generally dark in colour and has a high acid value and cannot be consumed directly, but requires further refining. As refining increases, the quality of the oil changes significantly, resulting in a significant loss of beneficial concomitants such as sterols, tocopherols and polyphenols.

The existing literature focuses on the extraction of coconut oil, the synthesis of fatty acid methyl esters and alkyl hydroxamic acids from coconut oil, but there is little research on the effect of the refining process on the quality of coconut oil. This paper focuses on the analysis of the changes in the physicochemical indexes and fatty concomitants of coconut oil during the refining process, in order to provide basic data for optimizing the refining process of coconut oil and guiding reasonable and appropriate refining.

The gross coconut oil, alkali refined oil, decolourised oil and deodorised oil were sampled from coconut oil processing enterprises. Raw coconut oil was produced by pressing dried coconut, with an acid value (KOH) of 7.4 mg/g and a peroxide value of 2.91 mmol/kg.

The alkali refined oil is obtained by alkaline refining and washing and drying of the gross coconut oil. The alkali refining temperature is 70°C. A 6.58% light alkali solution is added at 0.2% of the oil mass, mixed for 10 min, separated by centrifuge, washed and dried at 110°C under vacuum conditions.

The decolourised oil is obtained from the alkali-refined oil by adsorption and filtration with white clay. The amount of active white clay added is 1.5% of the oil mass, the decolourisation time is 30 min, the decolourisation temperature is 100°C and the vacuum degree is 94 kPa.

The deodorised oil is obtained by vacuum deodorisation of the decolourised oil. Deodorisation temperature 230°C, vacuum 0.3 kPa, deodorisation time 1 h.

37 fatty acid blends, α-, β-, γ- and δ-tocopherols (>95% purity), some glycerides (monoglycerides of 2-oleic acid, diglycerides of 1,2-dioleic acid, diglycerides of 1,3-dioleic acid), gallic acid, BSTFA TMCS silylation reagent and 5α-cholestanol standards, all purchased from Sigma, USA. Triglycerides (triglyceride CpCpCp, triglyceride LaLaLa, triglyceride PPP) standards, purchased from Larodan Fine Chemicals AB. Hexane, ethyl acetate, methanol and isopropanol are chromatographically pure; potassium hydroxide, glacial acetic acid, trichloromethane and anhydrous ethyl ether are analytically pure.

The refining process resulted in a significant decrease in the acid value (KOH) of coconut oil from 7.40 mg/g to 0.29 mg/g (p<0.05), and the peroxide value of coconut oil showed a significant decrease during the refining process (p<0.05). The deodorisation process resulted in a significant decrease in peroxide value (p<0.05) due to the removal of a large amount of oxidation products, reaching 0.80 mmol/kg. both the acid value and peroxide value indicators met the requirements of NY/T 230-2006 "Coconut Oil" for refined coconut oil.

The oxidation stability index of coconut oil showed a trend of decreasing and then increasing during the refining process. The highest oxidation stability index (54.29 h) was found in the gross coconut oil, probably due to the higher content of endogenous natural antioxidant components in the gross coconut oil compared to the alkali-refined and decolourised oils. However, as the refining process progressed, the natural antioxidant components were gradually lost and the oxidative stability index of alkali-refined oil decreased to 38.36 h, probably due to the loss of some polyphenols by the addition of alkali, which led to a decrease in oxidative stability. The lowest oxidation stability index (35.12 h) was found for the decolourised oil, probably due to the addition of active white clay, which has strong catalytic activity and catalyzes the oxidation of coconut oil to produce some small molecules, thus making the oxidation stability less stable. After deodorisation, the oxidation stability index increased significantly, which is mainly due to the deodorisation under high temperature and high vacuum conditions, where small molecules easily oxidised are removed and oxidation stability is improved.

During the refining process, the acid value and peroxide value of coconut oil were significantly reduced (p<0.05) and the refined coconut oil was more stable, while refining also brought about the loss of fat concomitants. The degree of impact of each refining process on the quality of the oil varied, with the deodorisation process having the greatest impact on the quality of coconut oil compared to the alkali refining and decolourisation processes.

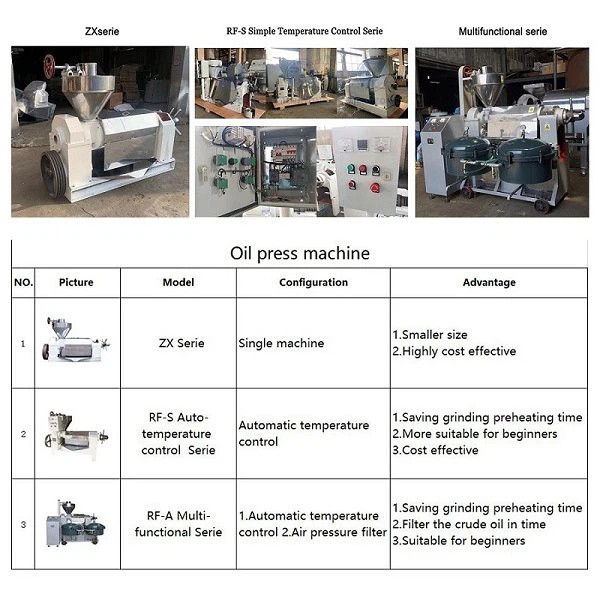

Recommended models

More details

shipping