Oil palm is the woody oil plant with the highest yield per unit area in the world. The yield per mu of its main product, palm oil, can reach 200kg, which is 5-6 times that of peanuts and 10 times that of soybeans. Palm oil in the traditional sense refers to the pressed palm fruit pulp, which is different from palm kernel oil obtained by pressing the nuts. Palm oil, soybean oil and rapeseed oil are also known as "the world's three major vegetable oils".

Palm oil is obtained by pressing the fresh palm fruit. Palm fruits grow in bunches and clusters, and each bunch weighs about 20-30kg and contains 1500-2000 fruits. Farmers pick palm fruit bunches in a cycle and must be transported to the factory for processing on the same day. The quality of crude palm oil depends on the integrity of palm fruit bundles. Once the palm fruit is damaged, it will quickly deteriorate, thus affecting the quality of crude palm oil.

The main products of the palm fruit crushing plant are crude palm oil and palm kernel, and the processing capacity is about 60~100 tons of palm fruit bunches per hour. For crude palm oil, it generally needs to go through processes such as sterilization, threshing, cooking, pressing, washing, purification, and drying.

Sterilization

Sterilization as the first step in palm fruit pressing is crucial to the quality of the final product palm oil. The purpose of sterilization is mainly to make the palm fruit easier to fall off from the fruit bunch and soften the peel, so that the oil is easier to separate out.

Threshing

The main function of threshing is to free the palm fruit from the bunch. The sterilized palm fruit bundles will be conveyed into the drum thresher, and the palm fruit will be separated from the stalk as the drum rotates.

Steaming and pressing

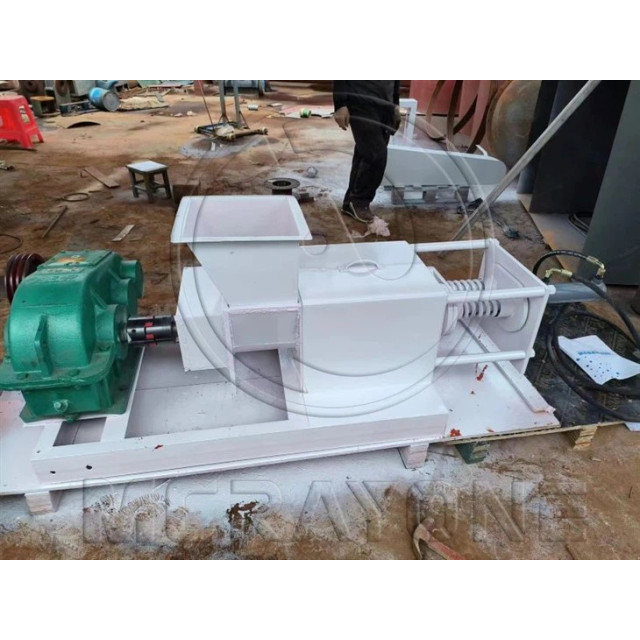

The threshed palm nuts are conveyed into cooking pots where they are reheated with direct or indirect steam. A central shaft with stirring fins is installed in the cooking pot, and the palm fruit is stirred accordingly, and the pulp becomes soft and peeled from the core at high temperature. The mixture is then sent to the pressing equipment.

|

Model |

Capacity |

Power |

Size |

|

AY-Z30 |

200-300kg/h |

/ |

1200*550*1050mm |

|

AY-Z50 |

400-600kg/h |

/ |

1450*1100*920mm |

|

YS-1.0 |

1-2t/h |

5.5kw |

1800*850*650mm |

|

YS-3.0 |

3-4t/h |

9kw |

1950*870*680MM |

|

YS-5.0 |

5-6T/H |

13.2kw |

2150*950*870MM |