Over the past few years, coconut oil has become one of the most popular cooking oils in the world and remains one of the leading sources of fat in many Pacific and Asian countries.

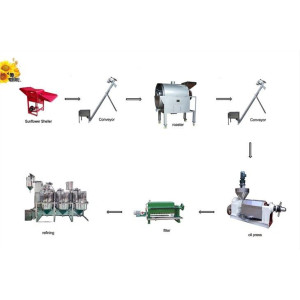

1. Copra conveying: the raw material of copra is massive solid, so it is not suitable to be conveyed by elevator; because the imported small scraper conveyor is too small, the feeding is not smooth, so the belt conveyor is selected, and its inclination angle shall not exceed 30 degrees, otherwise Easy to drop material.

2. Crushing: copra meat is a tough blocky solid obtained after drying coconut meat. Therefore, the problem of crushing copra meat must be solved first, so a copra crusher must be equipped.

3. Steaming and frying: through uniform heating to increase the oil yield of copra. However, due to the continuous stirring of the steamer and wok, the copra is easy to come out of the wok and drip oil along the main shaft, causing waste in the workshop and environmental pollution; at the same time, the materials are easy to agglomerate, which brings difficulties to transportation. Solution: reduce the pulverization degree of the material, reduce the stirring time, and clean the discharge nozzle of the steam frying pan and the discharge nozzle of the elevator frequently to prevent the accumulation of materials.

4. Oil extraction: Due to the different properties of crushed copra and ordinary oil, there may be problems such as no feeding, no cake, and no oil in the oil outlet of the pressing cage. So it is necessary to adjust the bead gap. When extruding the desiccated coconut material, there should be very little gap between the strips. After improving the steaming and frying conditions of the material, the feeding is normal, and the oil is mainly produced in the second stage and the third stage. It is worth mentioning that at the beginning of feeding, before the temperature of the pressing chamber rises, the flow rate of the material entering the pressing chamber should not be large, otherwise it is easy to form a thin paste at the feeding place, resulting in poor cake output or even sintering.

5. Oil clarification and filtration: Copra contains a lot of fiber, so crude oil contains a lot of slag. Therefore, a filter is required to filter solid impurities.

|

Item |

Specification |

|

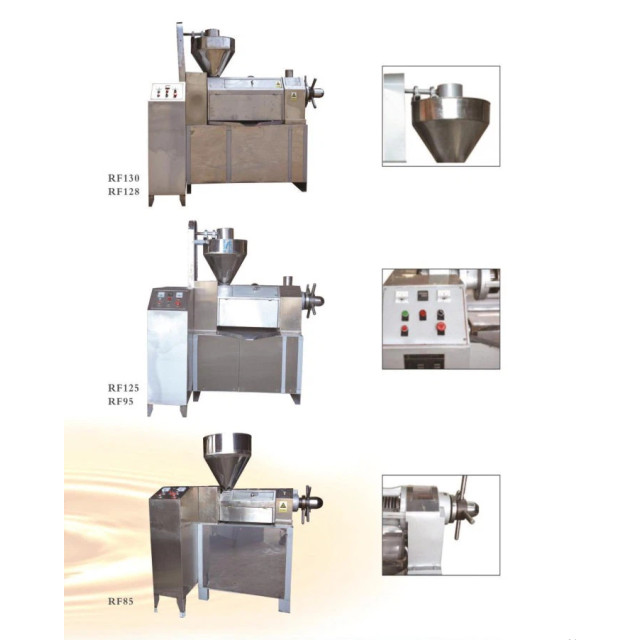

RF85 Auto-temperature control oil press |

Speed: 60-80 kg/h Capacity: 1.5-2 T/ 24hrs Power: 8.3 kw-4P Size: 1550*900*1280mm Weight: 450 kg |

|

RF95 Auto-temperature control oil press |

Speed: 150-200 kg/h Capacity: 3.5-5 T/ 24hrs Power: 13.6 kw-4P Size: 1900*1000*1970mm Weight: 740 kg |

|

RF125 Auto-temperature control oil press |

Speed: 210-300 kg/h Capacity: 5-7 T/ 24hrs Power: 17.6 kw-4P Size: 2100*1000*1970mm Weight: 775 kg |

|

RF128 Auto-temperature control oil press |

Speed: 300-375 kg/h Capacity: 7-9 T/ 24hrs Power: 18.2 kw-4P Size: 2000*800*1170mm Weight: 968 kg |

|

RF130 Auto-temperature control oil press |

Speed: 450-500 kg/h Capacity: 10-12 T/ 24hrs Power: 21.7 kw-4P Size: 2250*1100*2080mm Weight: 1135 kg |

This machine is a temperature-controlled oil press machine manufactured by our factory. If the factory needs to increase the oil yield of raw materials by controlling the temperature, this machine is suitable for priority, and its simple and elegant appearance is very popular among customers.

Unrefined coconut oil can be dry or wet extracted, while refined coconut oil goes through some additional processing steps. Refined coconut oil is mostly odorless and has a higher smoke point than unrefined coconut oil.

Refined coconut oil may be a better choice for baking due to its strong coconut flavor and aroma. If you use refined coconut oil the result will be without the taste and smell of coconut which may conflict with the taste of the product

However, if you like unrefined coconut oil and don't mind the taste, its low smoke point is unlikely to affect the quality of baked goods since the food itself will not reach such high temperatures, even at temperatures above 350 The same is true in the oven at 177C.

Either way, both coconut oils are the best vegan substitutes for butter in baking applications because they're both solid at room temperature.

And the oil is made by pressing the pulp of coconut. It belongs to "hard oil" in soap making. It can produce soap with strong foaming power and cleaning power, and the soap body is very hard. It is almost always used in making handmade soap Oil. Because coconut oil is almost composed of saturated fatty acids, especially lauric acid (accounting for 40%), which has antibacterial ability, the oil itself is very stable, and it is not easy to deteriorate after being put into soap.