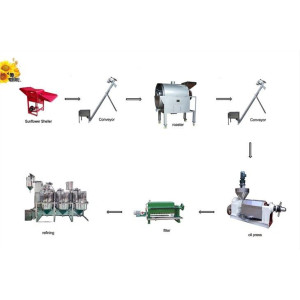

The working process

The two biggest features of this muti-function screw soybean oil press with vacuum filtration are the design of automatic electric control cabinet and pressure type oil filter equipment. In the process of using an automatic oil press to press oil, the automatic temperature control system is first opened, so that the internal temperature of the oil press is suitable for oil extraction, and then the fuel is transported to the press cage for oil extraction. The squeezed edible oil is filtered through the vacuum filter to remove the residue and obtain pure edible oil.

Component introduction

The vacuum filtration capacity integrated into the machine is equivalent to that of a standalone vacuum filtration system, eliminating the need for the user to procure an additional filter. This not only minimizes purchase costs but also reduces the overall footprint, making it a more space-efficient and cost-effective solution.

Our oil press is equipped with cutting-edge temperature control technology, enabling real-time monitoring of data. This advanced feature significantly enhances the oil yield while also adhering to the principles of sustainable production and promoting the adoption of green energy practices.

There are two components on the integrated machine, one is called the compressed air precision filter, and the other is called the oil-water separator. It is used to clean the compressed air, because the compressed air will contain dust, water.

Advantages

1.Improved cost-effectiveness. Affordable price. Apply a variety of fuel, such as camellia, hazelnut, sunflower, mustard, linseed and sesame. The expeller can be used for 6-10 years under normal conditions.

2.Components are made of high carbon steel, high-frequency quenching heat treatment can adapt to high temperature, high pressure continuous operation, to ensure that the equipment can run for a long time.

3.All-season application.

4. New oil transfer technology for automatic oil filtration. Oil extraction and oil filtration can be carried out simultaneously, and the feed to the finished oil takes only a few minutes.

5.Exceptional post-sales support and a strong market standing.

If you are interested, please contact MCRAYONE by email.