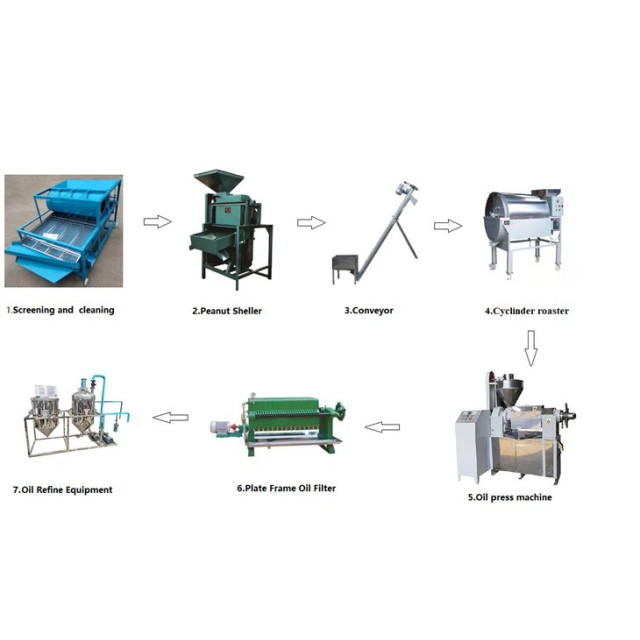

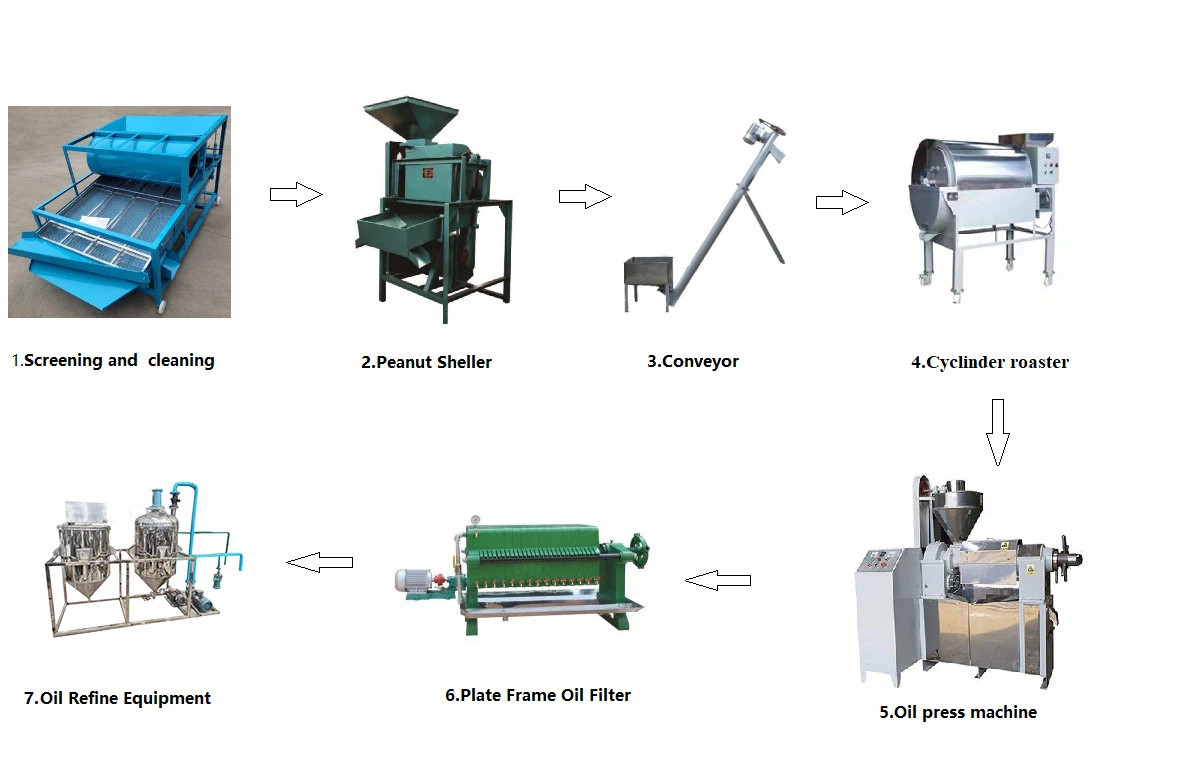

1、Cleaning and Drying of Peanut Fruits: Remove impurities from peanuts. Peanut fruits brought into the oil factory inevitably carry some impurities. If the dirt, stems, and leaves carried by the peanuts are not removed, they will not only affect the quality of oil and cake, but also adsorb a portion of the oil, reducing the oil yield. If there are stones, metals, hemp ropes, and other debris in the peanuts, it can also cause wear and tear on the peanut oil press machine components, leading to production accidents and affecting the process. Therefore, in order to ensure the smooth operation of the peanut oil press production, impurities must be removed as much as possible. For peanuts with high moisture content, it is also necessary to dry them for easy shelling. There are many methods for cleaning, and specific methods can be adopted based on the situation of the impurities. If the impurities are light, such as grass, stems, and leaves, the wind selection method can be used to blow away the impurities with airflow. If the impurities are small particles, they can be removed by selection. For some debris with a size and relative density similar to peanuts, if it is a soil block, it can be ground in a mud machine and then removed by screening. If it is an iron impurity, electromagnetic or permanent magnets can be used for separation.

2、Shelling: The purpose of shelling peanuts before the peanut pressing process is to reduce the adsorption of shells on oil, improve the oil yield; increase the processing capacity of the peanut oil press machine, reduce wear on the oil processing equipment; facilitate rolling and improve the quality of crude oil; improve the quality of cake, facilitating comprehensive utilization.

3、Crushing: Use a crusher to crush peanuts to a particle size that meets the requirements for rolling embryos.

4、Rolling Embryos: Use a single pair of roller embryo rolling machine to roll the peanuts into thin and uniform sheets. The requirements for sheets are small powder content, no oil leakage, and a thickness of less than 0.5mm.

5、Heat Treatment (Roasting): Destroy the cellular structure of the oilseeds, denature proteins, and cause phospholipids to absorb water and expand, meeting the requirements for pressing, improving the oil yield, and reducing phospholipid content. Heat treatment is an important process in the oil extraction process. Heat treatment includes wetting and heating of raw materials, called steaming or roasting in production, and the steamed or roasted raw materials are called cooked embryos. Raw materials that are pressed after heat treatment are called hot pressing, while those without heat treatment are called cold pressing. Peanuts are mainly hot pressed. The effectiveness of heat treatment has a direct impact on the smooth operation of the entire oil production process, the oil yield, and the quality of oil and cake.

6、Pressing: Peanut oil press machine is a small-scale oil press machine with a simple structure and high pressure. It can continuously process materials with low labor intensity. It can press a variety of oilseeds.

7、Filtering: Put the pressed crude oil into a centrifugal filter to remove impurities from the oil, improve purity, and enhance the quality of the oil.

|

Item |

Specification |

|

DCW100 Rolling Fry Seed Machine (Electricity) |

Capacity: 100-150 kg/h (120-150℃) 200-300 kg/h (80-100℃) Power: 1.1 kw-6P Size: 1450*820*1780mm Weight: 310 kg |

|

RF128 Auto-temperature control oil press |

Speed: 300-375 kg/h Capacity: 7-9 T/ 24hrs Power: 18.2 kw-4P Size: 2000*800*1170mm Weight: 968 kg |

|

YLB307 Plate Frame Oil Filter

|

Filter Area: 3m2 Capacity: 120-180 kg/h Plate Size: 355*355mm Plate Quantity: 13 pcs Power: 1.5 kw-4P Size: 1270*570*640mm Weight: 430 kg |

|

RE500-4 |

Capacity: 500KG/6H 4TANK |