Cotton seeds account for around 65% of the weight of the cotton seeds. When de-linting cotton seeds, you should try to increase the lint yield and reduce the crushing rate. In order to ensure the quality of the short lint, the lint yield of the first lint is controlled at 2-2.5%, and that of the 2nd and 3rd lint at 3-3.5%.

The processing of cotton seeds differs in the processes and equipment used due to differences in production scale and raw materials.

Composition and physical properties of cottonseed

1. Oil content: 14-20

2. Kernel oil content: 30-40

3. Hull oil content: 0.3~1

4. Seed kernel content: 45-60

5. Seeds with hulls: 40-55

6. Seeds with cotton phenol: 0.8~1.2

7. Kernel protein: 31-38

8. Phospholipids: 1.26~1.75

Oilseeds require different mechanical treatments, heat treatments and tempering treatments, which we call pretreatments.

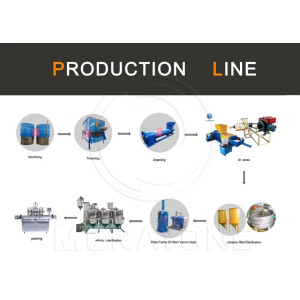

Pre-treatment of large yield cottonseed consists of: cleaning - shelling - shell-kernel separation - germ rolling - steaming - puffing - drying - pressing

Cleaning: (wind sorting, magnetic separation)

Purpose: to improve oil yield, oil cake and by-product quality; to increase oil yield and reduce losses; to increase equipment handling capacity; to reduce wear and tear on equipment; to ensure safe workshop production

Shelling: Different methods of shelling are used according to the different characteristics of the oil hulls, their shape and size, and the attachment of the hulls to the kernel.

1. By means of surface rough rubbing effect, make oilseed shells broken, such as disc type shelling machine, peanut shells, rapeseed shells

2. Crushing by impact with the wall. Such as centrifugal shelling to break sunflower seed shells, oil palm fruit shells

3. Crushing of oil materials by means of extrusion and shearing of the tooth rollers. Such as tooth roller shelling of cotton seeds, castor seeds, sunflower seeds, soybeans, etc.

Separation of shells and kernels

After shelling, cotton seeds are a mixture and these mixtures must be separated. The kernel goes into softening or germ rolling.

Embryo ginning

1. To destroy as much cellular tissue as possible, the oil under pressure causes mechanical denaturation of the proteins and facilitates steaming and frying.

Steaming and frying

After rolling, the material is moistened, heated and fried to create better conditions for oil extraction.

There are two types of steaming and frying.

A wet steaming and frying: the oil is first heated with water and jet, the water reaches 13-14%, then steamed and fried.

B dry steaming and frying: first heated, steamed and fried in steam, then treated with a screw oil press.

Pressing

By means of a screw oil press to obtain cottonseed crude oil

| Mcrayone Oil press machine | ||||||

| NO. | Model | Power | Capacity | Weight | Configuration | Mark |

| 1 | RF-A Multi-functional | 16.4~23.9kw | 3.5-5 T/ 24hrs 5-7 T/ 24hrs 7-9 T/ 24hrs 10-12 T/ 24hrs |

1100~1300 kg | 1.Automatic temperature control 2.Air pressure filter | 1.Saving 30-60min grinding preheating time 2.Filter the crude oil in time 3.Suitable for beginners 4.Designed for safety 5.Relatively large in size |

| 2 | RF Auto-temperature control | 13.6~21.7 kw | 3.5-5 T/ 24hrs 5-7 T/ 24hrs 7-9 T/ 24hrs 10-12 T/ 24hrs | 740~1135kg | Automatic temperature control | 1.Saving 30-60min grinding preheating time 2.More suitable for beginners 3.Designed for safety |

| 3 | RF-S Simple Auto-temperature control | 13.6~21.7 kw | 3.5-5 T/ 24hrs 5-7 T/ 24hrs 7-9 T/ 24hrs 10-12 T/ 24hrs | 753~880kg | Automatic temperature control | 1.Saving 30-60min grinding preheating time 2.More suitable for beginners 3.Cost effective |

| 4 | ZX Screw Oil Press | 11~30kw | 2.5-5 T/ 24hrs 5-7 T/ 24hrs 7-9 T/ 24hrs 10-12 T/ 24hrs 15-17 T/ 24hrs 16-20 T/ 24hrs |

702~1340 kg | Single machine | 1.Smaller size 2.Highly cost effective 3.Suitable for large production lines |