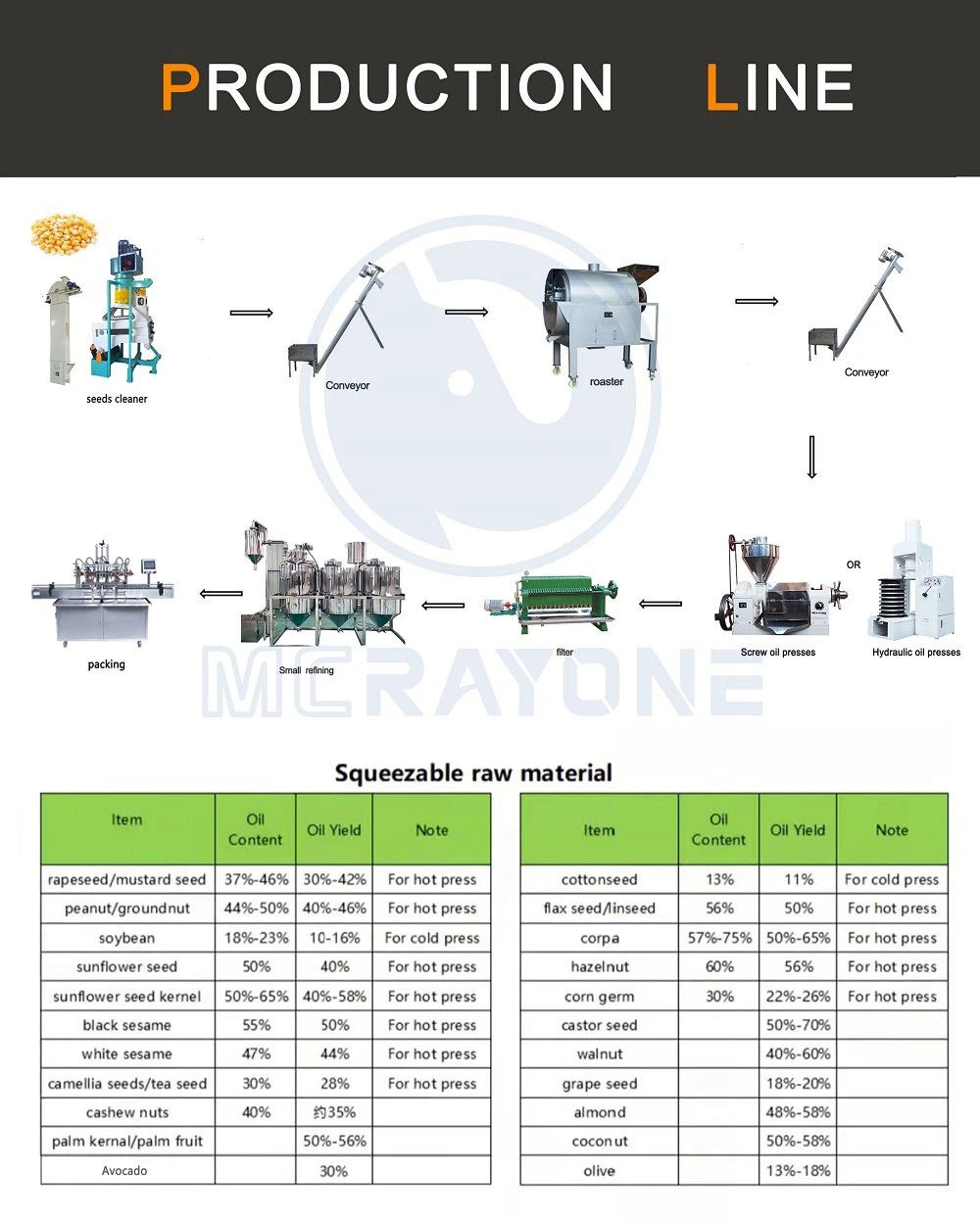

Moringa seed oil Production Line

Contain: Material pre-processing /Pressing /Refining/Packing/Feed

一、Basic information about Moringa seed oil

1. Unrefined Moringa seed oil is dark yellow with some unpleasant smell.

2. The antioxidant stability of the finished oil after cold pressing at low temperature exceeds that of extra virgin olive oil, which is suitable for edible and medicinal use.

3. Storage temperature should be 4℃.

二、Basic flow of production line

1.Raw material pre-processing

Main Equipment:Seeds cleaner/Sheller /Crusher/

This part is used to remove the sand and gravel from the seeds to make the seeds clean. Reduce wear and tear on subsequent machines and increase machine life

2.Pressing Part

Main Equipment:Conveyor/Roaster/Oil press/Oil filter

The machines and auxiliary equipment for the first part that we configure are designed based on production volume of 500KG/H

In addition, considering the rate of return, we recommend using the hot pressing process. Because it can reduce the residual oil rate to the greatest extent and the oil cake formed after hot pressing is more suitable for subsequent processing, such as turning into animal feed.

3.Refining Part

Main Equipment:Refining systems/Boilers/Oil storage tanks

Refined oil refers to the refining of crude oil,The impurities in the crude oil that are harmful to food and storage are removed to obtain refined oil that meets the national quality standards.

4.Packaging Part

Main Equipment:Filling machine/Capping machine/Labeling machine

(Automatic / Semi-automatic)

The oil yield of the raw materials is around 10%, so in one day, around 2250 liters of oil can be obtained. And this, will become the standard for us to recommend refining equipment and packaging machinery of refined oil.

三、Detailed equipment list

1.Impurity Removing Machine

| Name | Specification |

| QZ400 |

Capacity: 400-1000kg/h Power: 3kw/380v Size: 1550*900*2600mm Weight: 480kg |

2.Moringa seeds Sheller

| Name | Specification |

| Sheller |

Capacity: 200kg/h Power: 2.2kw/1.5kw 220v/380v Size: 65*88*98cm Weight: 98kg |

3. Steamer /Roaster

| Name | Specification |

| Roaster |

Capacity: 300 kg/h (120-150℃) 600 kg/h (80-100℃) Power: 1.5 kw-6P Size: 1800*1130*1450mm Weight: 630 kg |

4.Screw Oil Press / Hydraulic Oil Extraction

5.Oil filter

| Name | Specification |

|

Plate Frame Oil Filter |

Filter Area: 3m2 Capacity: 120-180 kg/h Plate Size: 355*355mm Plate Quantity: 13 pcs Power: 1.5 kw-4P Size: 1270*570*640mm Weight: 430 kg |

6.Oil Refinery

A:Refining / Filtration Process (Sesame Peanut Oil)

Crude oil → Dephosphorization → First filtration → Trophotrophic crystalline → Second filtration → Final filtration → Refined oil

B:Refining Process

Crude oil→ Dephosphorization→ Deacidification→ Dehydration→ Decolorization→ Deodorization Dewaxing (for sunfower seeds oil / corn oil )

Edible oil refining technology:

Refining oils is based on the difference between oil and physical and chemical impurities. It is about separating the fat and impurity by professional technical means, to improve the edible quality of the oil, the storage stability and the safety process.

The process of refining oils is divided into chemical refining and physical refining. Depending on the raw materials and production capacity, we may use physical and chemical refining design in batch, continuous. Refined oil can reach the first level (Chinese standard).

Application Case:0.5/2-3/More than 5TPD