1. Product introduction

Cottonseed contains 39-52% hull and 48-61% kernel. The shell contains 0.3 to 1% oil. Cotton kernels contain 30-35% oil and 35-38% protein. Cotton seed contains 0.8% to 1.3% gossypol. The traditional production process of cottonseed oil is pre-pressing or pressing. The following is the flow chart of the cottonseed oil production line. The pressing process is cold pressing or hot pressing According to your needs, relevant personnel will give you professional advice.After being refined, it can be eaten by humans. It contains a lot of essential fatty acids, and it is most suitable for mixing with animal fat.Do not eat crude oil will harm your health。

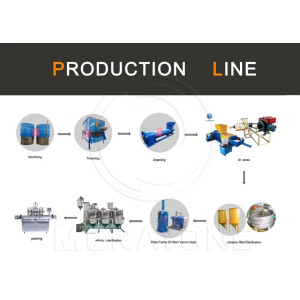

2.Cottonseed pressing process

1.First put 1/4 or 1/3 of the cottonseed in the pot, and then slowly stir fry. During the frying process, avoid high temperature in the pan, which will cause the cottonseed hull to burn

2.Need fixed sieve and manual sieve to remove impurities and soil

3.When grinding, the material should be less,and the flow should be even and continuousTo make the cottonseed easy to break, the speed of the grinder should be faster

4.Sprinkle water with the ring groove of the milling roller. When milling, sprinkle water while turning the seeds at the same time, so that the draft of the billet is uniform and the milling is consistent

5.Pour the hair embryo into the steamer and flatten it by hand. The temperature, humidity and water level of the hair embryo should be the same

6.Then put the material into the oil press

7.The crude oil squeezed out by the oil press has impurities and is filtered after cooling

8. Put the filtered crude oil into the refining before eating