Before starting to produce edible oil, experienced oil producers know that the quality of the oil seed itself, the quality of the machines and equipments, the operation of staffs and other comprehensive factors are not to be ignored in the oil extraction line. Even with a fine production programme, perfect machines and equipments and skilled operators, neglecting possible problems with the raw seeds themselves can bring about a number of problems later on that can affect cost expenditure.

Therefore, knowledge of oil seeds, such as properties, storage methods, pre-treatment before oil extraction and other related knowledge needs to be well understood. You can get the relevant technical knowledge support from the experienced professional oil press machinery factory and choose the right oil press production line solution, which can help you avoid a lot of wrong choices and save time and money .

5TPD OIL PRODUCT LINE Main machine

|

ZX105 Screw Oil Press

|

|

Speed: 150-200 kg/h Capacity: 3.5-5 T/ 24hrs Power: (7.5-11 kw)-6P Size: 1600*700*1350mm Weight: 530 kg |

|

DCW63 Roaster (Electricity) |

|

Capacity: 80-100 kg/h (120-150℃) 160-200 kg/h (80-100℃) Power: 0.75 kw-6P Size: 1200*760*1100mm Weight: 255 kg |

|

RF600-S Oil Filter |

|

Capacity: 100-120 kg/h Power: 2.2 kw-2P Size: 855*690*1080mm Weight: 190 kg Filtering Barrel Diameter: 610mm |

|

Stainless steel oil refining |

|

Capacity: 5TPD

|

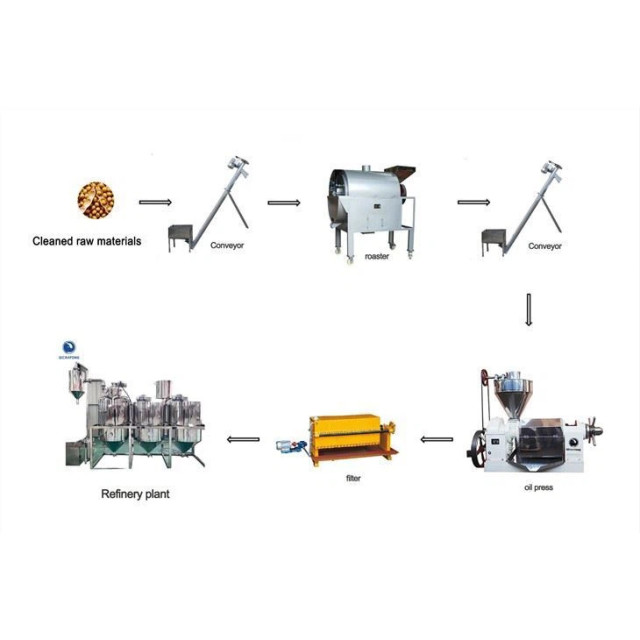

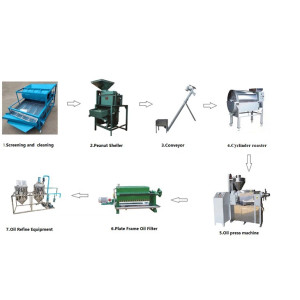

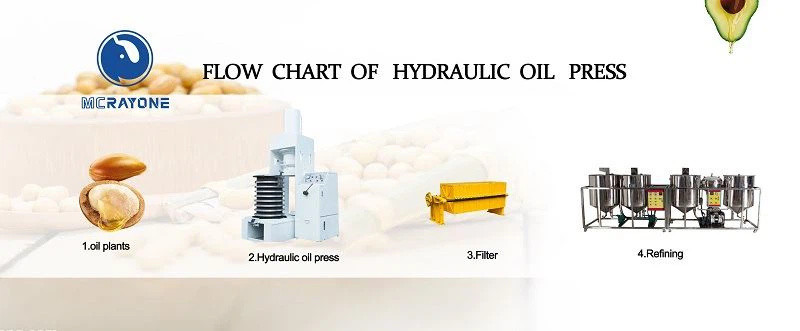

Working principle

When the oil press is running, the pre-processed material enters the press chamber from the hopper, and due to the pressure generated by the sharp change in the volume of the press chamber space from large to small and the propulsion of the screw shaft,the resistance of the multi-petal circular curve in the press ring, and the combined effect of the friction between the raw materials squeezing each other.

Thus generating a strong pressure to squeeze out the oil from the materials and flowing out from the oil gap between the press bar and the press ring.

The residue is squeezed into cakes and discharged from the end of the screw shaft.

How to connect the motor to the machine

1. Only ZX85 can customize 220V(Different prices for customization)

2. Motor to the power supply with a direct wire connection (see the following diagram for the specific connection method)

* If you need a start-stop switch, customers can find an electrician to set a switch between the power supply and the motor, responsible for motor start-stop (if it is a temperature-controlled oil press, wired to the control cabinet, there is a start-stop switch on the cabinet directly control)

Regular motor 380V/50HZ/3Phase

1.From the power fire wire, zero wire to the motor

Motor: red area zero wire, blue area fire wire