The process of pressing palm kernel oil and palm fruit oil are two different processes. The process of pressing palm kernel oil includes the following steps: fiber and kernel separation, kernel grading, shell and kernel separation, crushing, steaming and stir-frying, pressing, and filtering.

1. Fiber and kernel separation: Initially, fiber and kernel separation equipment is used to separate the fiber material from the palm kernel. This facilitates the processing of subsequent operations and reduces equipment wear. The fiber material can be used as biomass fuel, while the palm kernels are transported to the kernel grading equipment for further processing.

2. Kernel grading: The separated palm kernels are transported to the kernel grading equipment, where they are classified into large and small kernels based on their quality. This is advantageous for the subsequent separation of shell and kernel.

3. Shell and kernel separation: The different-sized palm kernels are then separately transported to the shell and kernel separation equipment. By adjusting the parameters of the separation machine, the shells of different-sized palm kernels are separated from the palm kernels, reducing equipment wear caused by the palm kernel shells.

4. Crushing: The separated palm kernels are then crushed to reduce their particle size and increase the contact area, facilitating the transfer of temperature and moisture in subsequent processes.

5. Steaming and roasting: The crushed palm kernels are then transported to a high-temperature steamer for steaming and roasting. This process adjusts the temperature, moisture, and humidity of the palm kernels to prepare them for pressing.

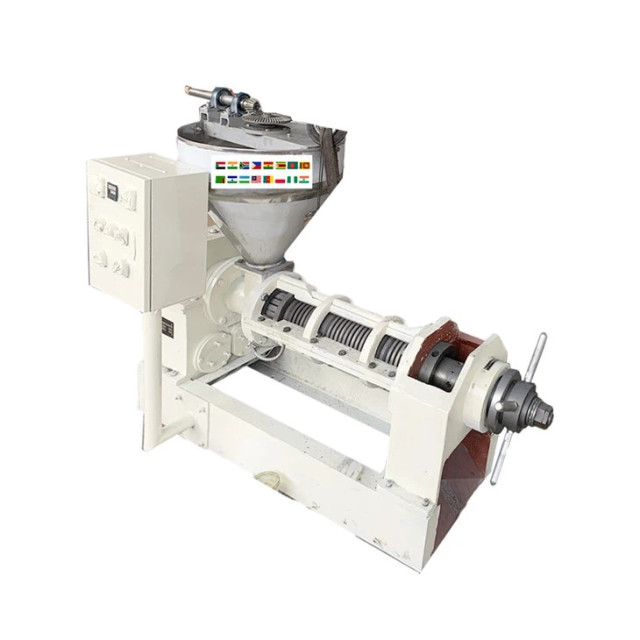

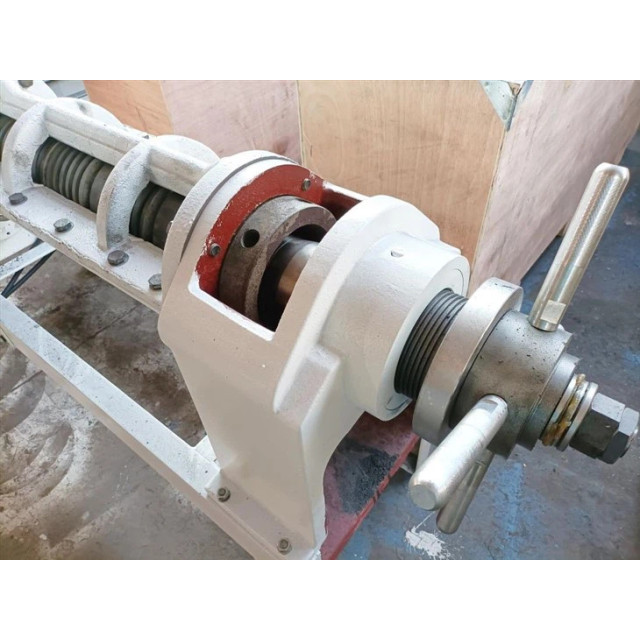

6. Pressing: The steamed and roasted palm kernels are sent to a palm kernel oil press machine, where the oil is continuously squeezed out by the pressing screw. After pressing, crude palm kernel oil and pressed cake are obtained. The crude oil is transported to the next processing step, while the palm kernel oil press machine is designed specifically for palm kernels, with easy operation, maintenance, and a high degree of automation.

|

Item |

Specification |

|

RF95-S Simple Auto-temperature control oil press |

Speed: 150-200 kg/h Capacity: 3.5-5 T/ 24hrs Power: 13.6 kw Size: 1690*840*1370mm Weight: 695 kg |

|

RF125-S Simple Auto-temperature control oil press |

Speed: 210-300 kg/h Capacity: 5-7 T/ 24hrs Power: 17.6 kw Size: 1900*1300*1350mm Weight: 720 kg |

|

RF128-S Simple Auto-temperature control oil press |

Speed: 300-375 kg/h Capacity: 7-9 T/ 24hrs Power: 18.2 kw Size: 2000*1200*1170mm Weight: 995 kg |

|

RF130-S Simple Auto-temperature control oil press |

Speed: 450-500 kg/h Capacity: 10-12 T/ 24hrs Power: 21.7 kw Size: 2100*1600*1380mm Weight: 1135 kg |

7. Filtering: Finally, the crude palm kernel oil is filtered using a plate and frame filter, resulting in clear palm kernel oil. If your budget allows and the local market requires higher quality palm kernel oil, the filtered palm kernel oil can be further processed using refining equipment, which not only improves the quality of the oil but also increases your profits.

The above is the process for small-scale palm kernel oil pressing, suitable for small palm kernel oil pressing plants. If you are interested in this pressing process and would like to learn more, please feel free to contact us.