What machinery is needed to produce palm fruit oil?

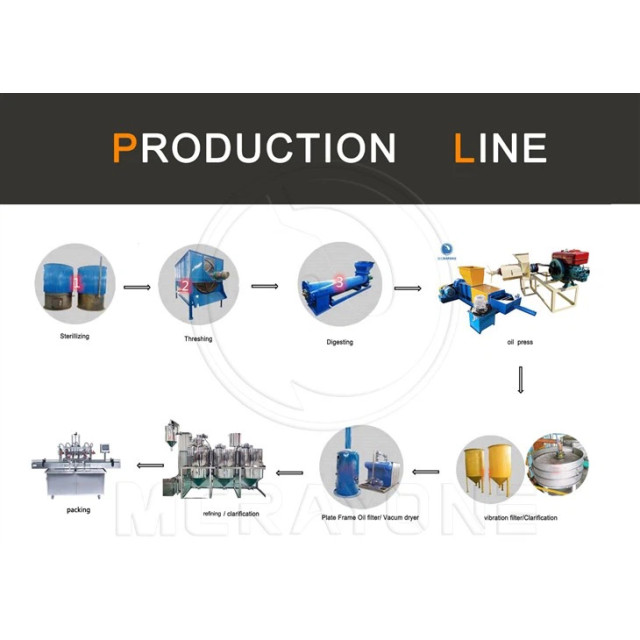

As one of the three major edible oils, palm oil is the choice of many food oil factory customers. MCRAYONE We provide customers with high-quality equipment and professional technical guidance.The process is as follows:

(1) First, the fresh palm fruit bunches are sterilized with steam. The sterilization can effectively inhibit the activity of splitting enzymes, ensure the quality of palm oil, reduce oil loss, and make the palm fruit soft and easy to separate. The specific method is to put fresh palm fruits into a sterilization tank, then use steam to carry out the cooking and fermentation process.

(2) Send the sterilized palm fruits to the threshing machine for threshing. After the threshing is completed, Place in a mashing machine for mashing; palm fruit should be mashed before pressing in order to press out the oil more effectively.

(3) Send the defruited and mashed palm fruits to a double-screw oil press for pressing to obtain crude oil;

(4) Filter and separate the crude oil through a vibrating separation screen. After removing coarse residues such as fibers, the clean oil is stored in the clarified oil tank, and then passed through the oil purification separator for further waste purification;

(5) The pure oil obtained after separation and filtration is heated to a certain temperature by a plate heater, and then the residue in the oil is drained by a vacuum dryer to obtain the finished oil.

In order to make full use of palm shells, the method of the present invention also includes the following steps:

(1) Send the fiber cake and brown core overflowing from the end of the double-screw oil press to the cake crushing auger to crush, and then send the fiber cake and brown core to the fiber core separator to separate the fiber and brown core.

(2) After the separated brown kernels are further air-dried through a blast dryer in the storage tank, the brown kernels are separated from the shells in a centrifugal separation and shelling machine, and the separated kernels are sent to the core through an elevator. Shell separator, the core shell is sent to the core shell dust collector through the outlet pipe, and the kernel enters the kernel dryer to be dried to obtain palm kernel; the outlet of the fiber dust collector and the core shell dust collector pass through the same feeding device The core-shell fiber is sent to the rice husk combustion furnace as fuel to generate steam for use in the system.